Unlock the Secrets to Cutting Machining Costs with Adaptive Toolpath Strategies

Discover How to Reduce Machining Time, Improve Efficiency, and Save on Costs

Download Your Free Ebook Today

In today’s competitive manufacturing landscape, reducing production costs while maintaining quality is crucial. Adaptive Toolpath Strategies offer a cutting-edge approach to machining, improving efficiency, and reducing waste.

With our free ebook, “Cutting Costs with Adaptive Toolpath Strategies,” you’ll gain actionable insights into how these strategies can enhance your operations and increase profitability.

Why Download This Ebook?

Maximize Tool Life and Save on Replacement Costs

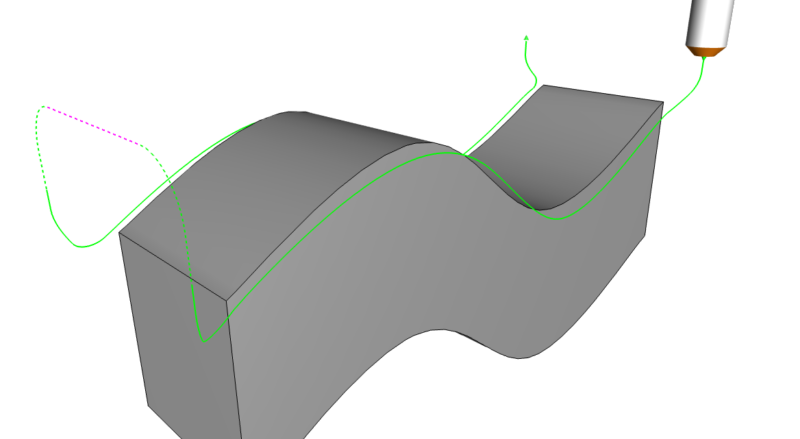

Adaptive Toolpath Strategies are designed to reduce tool wear by maintaining consistent cutting conditions.

Enhance Machining Efficiency for Faster Production

With adaptive feed rates and optimized cutting parameters, you can dramatically reduce machining time.

Achieve Precision and Quality Across All Materials

Adaptive toolpaths adjust to the specific properties of various materials, ensuring a consistent, high-quality surface finish and dimensional accuracy.