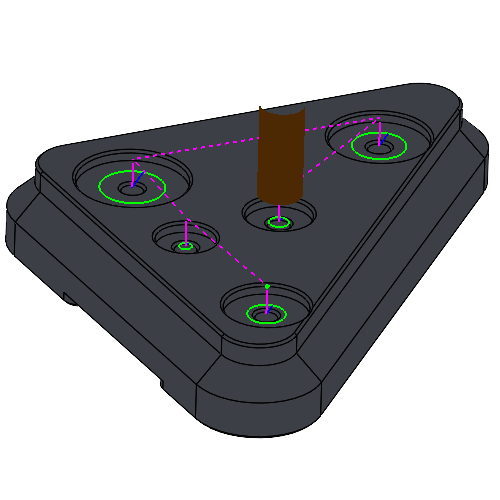

Lead From Center

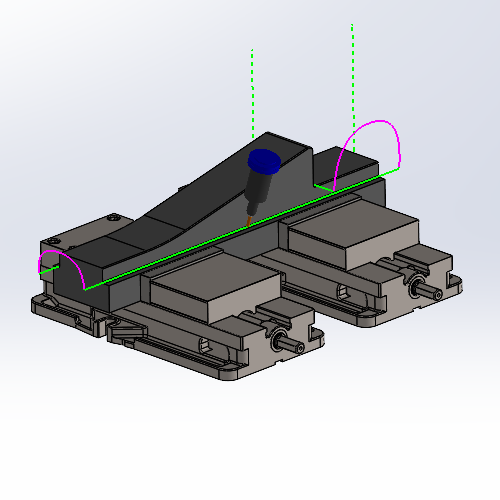

The new Lead from Center option simplifies creating leads at the center of toolpath chains, addressing a common challenge. It automatically finds the center-most point of any shape, eliminating the need for manual measurements and calculations.

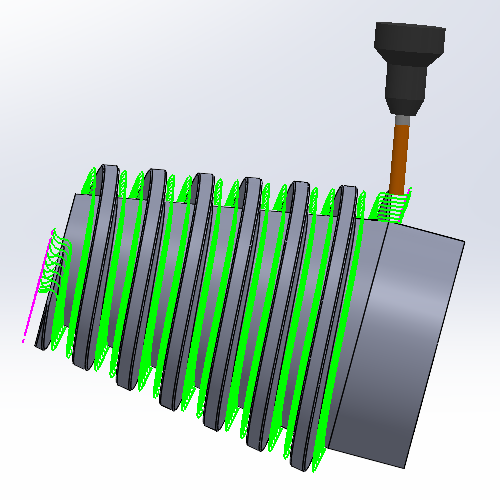

Conical Machining

The new Conical Machining option solves issues with machining conical shapes, which previously caused steps and air cutting. By selecting the checkbox on the Patterns page and setting the Cone Angle, the toolpath is now optimized for conical shapes, eliminating previous limitations in 4 Axis Advanced Rough and Finish operations.

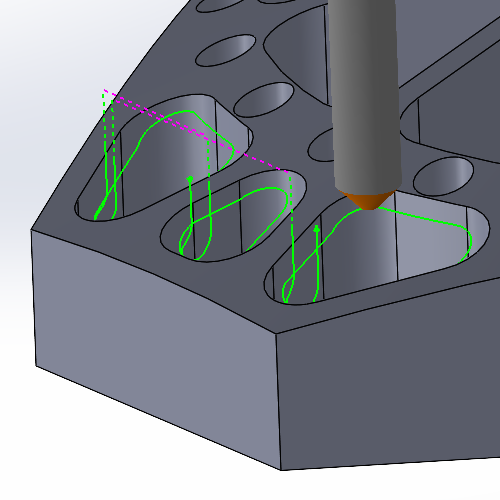

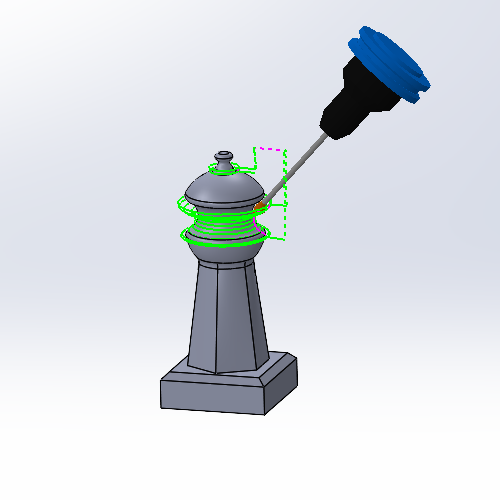

New Deburring Toolpath

The improved Deburring operation now allows you to easily apply toolpaths by simply selecting solids from the graphics area, automatically focusing on the necessary areas without the need for extensive geometry selections or manual adjustments.

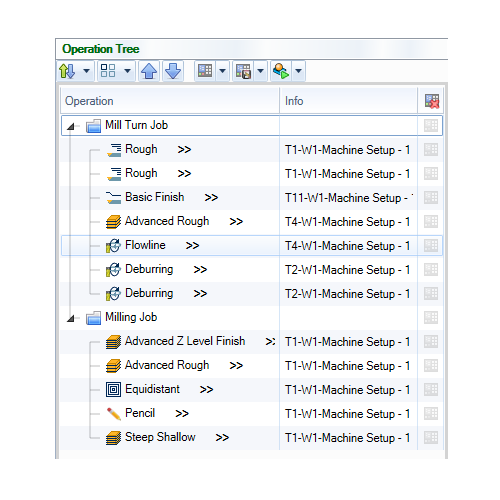

New CAM Tree Enhancements

The Machining order dialog has been replaced by a new Operation Tree, improving workflow by showing all jobs, tools, and assigned operations in the Tool Tree. Mill and Lathe jobs now support MDI (manual data input), allowing manual machine movement for more control over operations.

Surface Based Toolpaths

The new “Tilted with fixed angle to surface normal” option adds more control to Surface toolpaths in multi-axis machining. It allows you to adjust tool tilt based on the surface normal, which was not possible before. Simply select the option, choose a reference surface, and set your angles.

5 Axis Milling

The Undercut option in the Advanced Z Level Finish now supports 5 Axis machining. Previously unavailable in 5 Axis operations, you can now use spherical tools for undercutting by selecting a check on the Gouge Check page and setting the strategy to Tilt tool. You can also control the machined area with the “Extend undercut area” value.

Solidworks V12

BobCAM V12 is one of the most comprehensive CAM packages available for Solidworks users. It offers multi-axis milling, turning, wire EDM and more, as well as support for 3D geometry and 2D drawing files from Solidworks.

BobCAM offers different levels of integration with Solidworks including:

- 2-5 Axis Milling

- Lathe/Mill Turn

- Wire EDM

V12 introduces new features and enhancements, including a Wire EDM module and a redesigned BobART interface for improved workflow.

The new Operation Tree and Tool Tree offer greater control over operation posting and toolpath patterns. Additional updates include Finishing Spring Passes, advanced Leads with point picking and automatic center options, and improvements across 2, 3, 4, and 5 Axis machining.