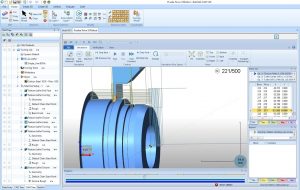

Supercharge Your Efficiency

with Integrated CAD-CAM Tools

Enhance your lathe programming experience like never before with our cutting-edge, integrated CAD-CAM solutions. Our software is designed to revolutionize every stage of your workflow, providing seamless transitions from design to simulation and refinement. By automating complex processes and minimizing manual tasks, our solutions allow you to focus on what matters—achieving precision and accelerating time-to-market.

Why use BobCAD-CAM for Lathe?

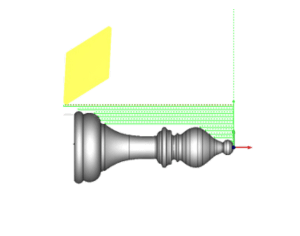

Lathe Cutting Pattern

Maximize efficiency with BobCAD-CAM’s smart cycle programming, streamlining linear cuts and material removal.

Achieve precise results faster – reimagine lathe projects with our innovative solution.

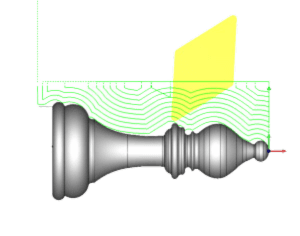

Lathe Offset Cutting Patterns

Discover the power of CAD/CAM’s Offset cutting strategy with BobCAD-CAM.

Move beyond linear movements and let your tool intelligently follow the final profile shape for optimized roughing processes.

Simulation and Collision Checking