Revolutionize CNC Workflow with Automatic 5-Axis Tilt

Eliminates collisions and improves quality

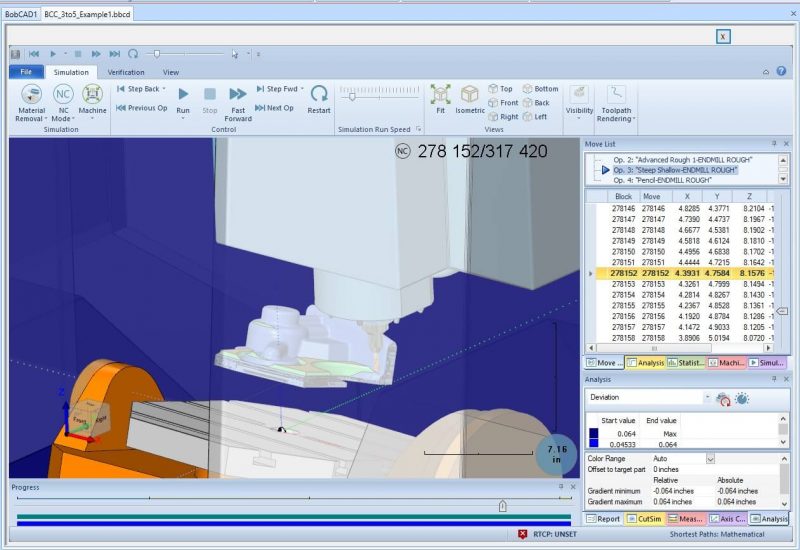

Automatic 5-Axis Tilt dynamically adjusts tool angles to eliminate collisions, even in challenging areas like walls and horizontal surfaces. It ensures precise cuts by maintaining safe distances, while its deviation analysis tool compares the cut geometry to the original model, guaranteeing quality.

Solidworks V13

BobCAM for SOLIDWORKS V13 delivers powerful, integrated CAM for 2-5 Axis Milling, Lathe/Mill Turn, and Wire EDM, all within the SOLIDWORKS environment. It supports both 3D models and 2D drawings for a seamless design-to-machining workflow.

V13 adds a Version Migration Utility, smarter Hole Recognition, Custom Roughing Tools, and improved Operation and Tool Trees. With features like Finishing Spring Passes and enhanced Advanced Leads, V13 boosts programming speed and machining precision.